Mechanics of Solids Laboratory

Faculty In charge – Dr. S. S. Pendhari

Supporting Staff – Mr. R. D. Haryan (Lab Instructor)

Mr. Rahul More (Hamal)

Sr. No. | Specialized Equipment Name | Equipment Details |

|---|---|---|

1 | Izod Impact Testing | Model FIT- 300N as per standard supply. Manufactured by Fine Testing Machines |

2 | Brinell Hardness Testing Machine | Model TKB-3000 as per standard supply. Manufactured by Fine Testing Machines |

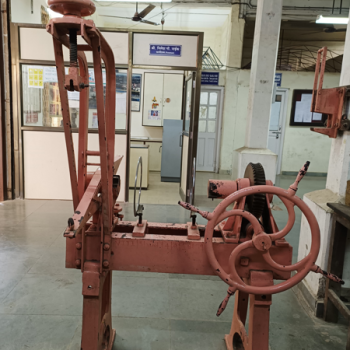

3 | Flexural Testing Machine | Lancashire Dynamo & Crypto Ltd. Manchester & Willesden |

4 | Universal Testing Machine | Saikiran Enterprises ISO 9001:2015. Capacity – 30TON |

5 | Compression Testing Machine | EIE Instruments Pvt. Ltd capacity- 300T |

6 | Shear Testing Machine | Shear Attachment for Universal Testing Machine |

7 | Torsional Testing Machine | Material - MS |

8 | Hand Compression Machine | Saikiran Enterprise Ltd |

List of Experiments (UG)

Tension test on mild steel bar

Elastic modulus of concrete

Tension test on tor steel bar

Shear test on mild steel bar

Tension test on steel plates

Flexural test on steel plates

Bend and re-bend test on mild and tor steel

Torsion test on mild and tor steel.

Brinnel’s Hardness tests on metal specimen

Impact test on metal

Compression test on wood

Tensile test on wood specimen

Flexural test on wood

List of Experiments (PG)

Evaluation of material properties (Modulus of elasticity E and Poisson’s ratio µ) of concrete and steel using strain gauge.

Evaluation of bending moments and deflections in a cantilever beam using strain gauge and dial gauges respectively.

Evaluation of torsional moments and rotations in a shaft using strain gauge transducer and dial gauges respectively

Load test on steel/RCC flexural elements (beams and slabs)

Evaluation of buckling load of steel column- applications of load cells

Evaluation of structural elements for free vibration characteristics using strain gauges/accelerometers

Use of Schmitz hammer to estimate in-situ strength of concrete and estimate of depth of carbonation.

Use of UPV to estimate, E value, quality / density of concrete.

Use of half-cell potentiometer to estimate corrosion potential in RCC element.

Use of Icor technique to estimate corrosion levels in the RCC elements.

Photo Gallery